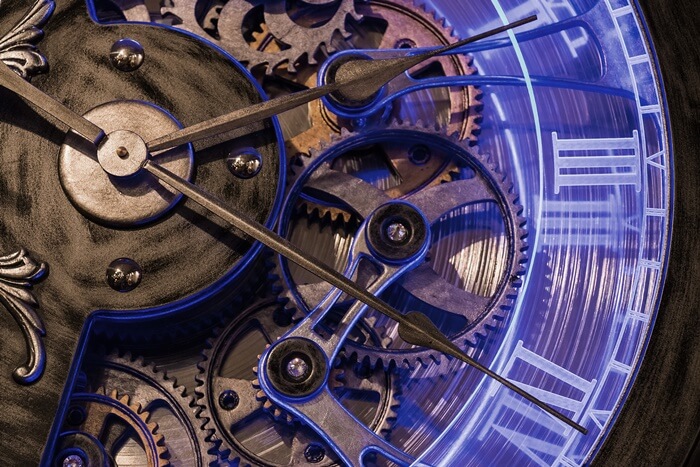

“Engineering plays a crucial role in product design and must be in synchronization with complementary matters. Cooperation of design and engineering enhances practicality and efficiency of the product development process. During the process, we turn challenges into opportunities and receive effective results. We offer our clients the advantages of combining two disciplines: design and engineering. We also support innovative concepts and pay close attention to reporting.”

Product Development: Where Design and Engineering Meet

1. Why did Arman Design find it necessary to include engineers into their team?

Murat Armağan: “Arman Design is a platform where designers and engineers work together to analyze both the design and engineering aspect of a product. Engineers who are specialized in design engineering have the technical knowledge and design skills to understand and actualize the main design. What makes us different is the fact that we support different disciplines within the same environment and allow them to enrich one another.

In our work model, designers get to understand the engineer’s approach and integrate the engineer perspective into their work. The fact that the two disciplines can compromise on behalf of the true design shows the real value of Arman Design. The visual data provided at the end of the project (data prepared for packaging, website, registrations, etc.) and engineering data (digital drawing and relevant information) provide great comfort to the client.”

2. Regarding the fact that Arman Design team has engineers as much as the number of designers, what does it tell us about the project management approach? How can you define the relationship between design and engineering?

When designers and engineers work in a single shared space, information exchange becomes inevitable. So that potential problems get solved before they get any bigger. Effective interdisciplinary approach is what makes the industrial product development process smooth and successful. Otherwise, the disconnection between the engineer and the designer disrupts the value created by the design.

Engineers interpret and actualize any design within the framework of his/her own knowledge, skills and experience. If engineers and designers work separately, then engineers will have no control mechanism during the process. It is important because design is relative. Designers create their design through their subjective perception, knowledge and skill. Even the smallest details are deliberate decisions. An object is designed within a certain framework including user research, aesthetic quality, conceptualization and many other well-thought-out design elements.

3. How do your designers and engineers approach to a product prototype which is a result of the collaborative work?

Prototype evaluation is one of the most critical stages of an efficient product development process. As the field test takes place, the visual and physical properties are evaluated. Prototypes are analyzed with these questions in mind: To what extent did it solve the problem? Do the test results show the reliability of the design? Can it compete with similar solutions? Are the production costs low enough? Is it profitable to mass produce? After the prototype production and field tests, pilot production begins. After some necessary amendments, the production stage comes to an end.

The material and physical constraints, unpredictable problems, commercial concerns and competitive environment surely affect the design outcomes. Users’ perception, marketing and sales strategies are also factors that affect product quality and cost.

4. What kind of problems arise when engineers and designers work together? For instance, does the technical details undermine designer’s creativity?

Design doesn’t consist of a single stage and a product is analyzed throughout many stages. In the early periods of the intense creative process, we don’t let the technical details and engineering processes restrict designer’s ideas. Design is essentially an innovative and evolving process. In order to get the design process going, sometimes we may have to make decisions with insufficient data. However, we have the know-how for when to integrate engineering into the design process.

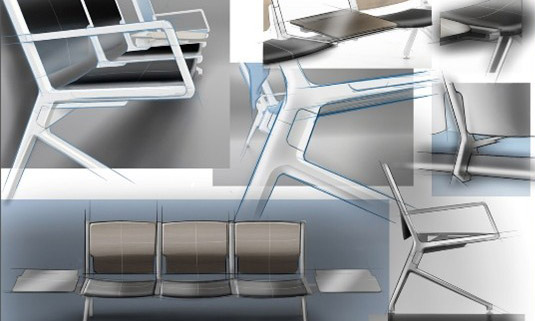

In the development and decision-making processes, visual and verbal communication reach its peak. Engineering design process becomes successful only if different disciplines are able to effectively communicate and coordinate with each other. The stages of the process is as following: research, design-analysis, development, prototype production, quality control, and testing.

5. Can engineering constraints turn into an opportunity to increase the value of the design?

Collaboration of engineers and designers is the guarantee of a consistent product development process. This is one of the most important benefits of working in an open office environment. In Arman Design, whatever we design is the final outcome. Designers examine the products aesthetically and economically. They determine how the products should be produced and what kind of materials should be used. At this stage, designers work closely with engineers so that time is productively and effectively used.

Engineering design is one of the primary and mandatory stages in product development and / or product differentiation. It has an indispensable importance in R&D studies. Engineering design is one of the basic studies in obtaining patents and trademarks, especially in the machinery manufacturing industry. In this aspect, it definitely provides an opportunity in the global competition.

6. What is the role of engineers in production management? What problems may arise during the production phase if there were no engineers in your team?

Engineering is a process that must be carefully managed. This is a vital step in actualizing a product. The project plan, technical solutions, innovative approach, material selection, and workmanship should be managed in full synchronization to get the best results.

Another benefit is the opportunity to develop certain processes from scratch. If the client doesn’t provide the necessary production methods and techniques, most probably the design cannot be actualized. However, Arman Design consists of experienced members with diverse backgrounds, and it allows them to create added value. With their experiences and resourced gained from different projects, they can share information on production, technicality, components, or application. We can call this a R&D for production. Therefore, Arman Design can make challenging processes possible with a research and interdisciplinary mindset.

7. What should engineers and designers keep in mind to maintain this creative collaboration? What actions did Arman Design take to facilitate the team work?

At the beginning of each project, we analyze the requests and needs of both our client and the user. We prepare an outline according to this analysis. We design our products to make life easier for the users and add joy to their everyday lives. This is only the beginning of the product development process. Our multi-disciplinary team gives importance to functionality as well as aesthetics. Our expert engineers design technological products which are ready to be produced from A to Z. The process starts with an idea and carried out with professional and effective methods.

From conceptual product design to production planning, we develop feasible products by using CAD engineering tools. Engineering services include detailed production service, production data, cost analysis and product diversification. Investors, suppliers and engineers must be in an efficient environment to develop a strong and feasible project. The strong connection between different parties shows positive results in the end.

The creative team of Arman Design, our clients and partners, we all work as a team to design future investments. We design for life. We design products that shape the future, connect with its users and gain a sustainable competitive advantage in the market. You can review our services in detail on our Services page.

From TRT Documentary to Modern Design Philosophy: The Anatomy of Industrial Innovation with Arman Design

From TRT Documentary to Modern Design Philosophy: The Anatomy of Industrial Innovation with Arman Design  The Future of Industrial Design in Turkey

The Future of Industrial Design in Turkey  Design + Engineering: More Than Aesthetics

Design + Engineering: More Than Aesthetics