İntegration of advanced digital production methods are expected to create new opportunities in the fields of computer science, nanotechnology and biotechnology. In the past century humans and machines were the building blocks of factories, in the future software, computer-aided hardware and cloud-based data infrastructure will be the building blocks of smart factories. In addition to production efficiency, advanced manufacturing methods will provide advantages to workers, societies and environment. Advanced digital transformation will open a new era in production. Developing countries will particularly benefit from technologically advanced production. This article is a deep-dive into advanced industrial technologies, their future and their potential.

Advanced Production Technologies and Industry 4.0

Industrial Revolution and Production

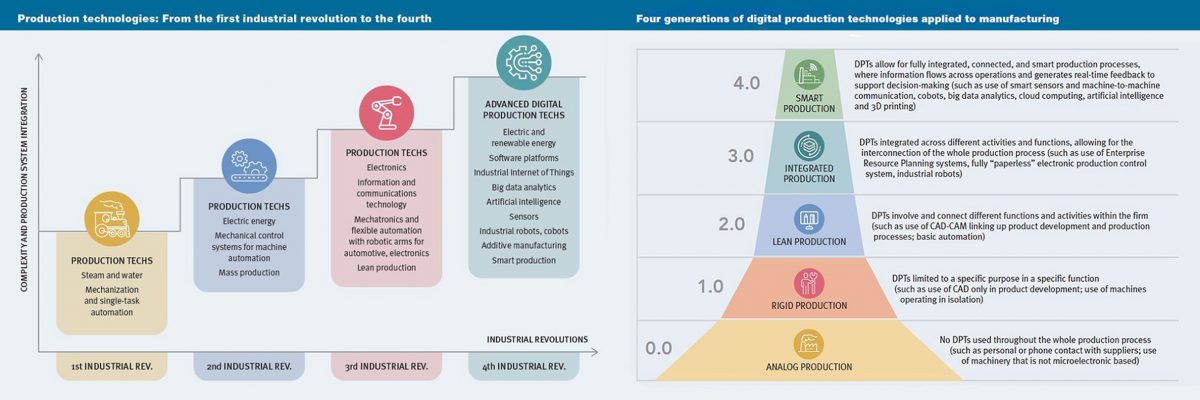

Factories are using many production methods and technologies developed during the first industrial revolution. Scientists point out that production speed and efficiency of digital factories will to open a new era of economical and social well-being. Yet many producers resist change and still base their production on 20th century methodologies. The first industrial revolution fundamentally changed global production patterns. In short, it began in the seventeenth century with the invention of steam-powered construction machines to meet the needs of growing populations. Steam-powered machinery and mechanization of factories significantly speeded up production and reduced the need for workers. In a similar vein, the second industrial revolution, started with the aim of meeting the unprecedented demand for cars with internal combustion engines. In an effort to meet customer demands many companies, primarily automobile factories, started developing new production methods and techniques.

Consequently, carmaker Henry Ford made the most influential break-through in the history of mass production. He designed assembly lines and the developed mass production methods for his factories. In this way, Ford both increased its capacity and started to shape the conditions of economic production. One of Ford’s young engineers adapted hooked line system in slaughterhouses to the automotive industry. Ford’s version of the system increased production speed and significantly reduced cost per product. The assembly line system, which lowered the price of a car from $575 to $280, made cars accessible to everyone. This impact created by the automobile industry initiated a sociological transformation all over the world.

Similarly, in the mid-20th century, research to reduce the size of electrical appliances led to the invention of semiconductors and primitive computers. Consequently, discovery of new materials made production of tiny components a reality. Without a doubt, these new technologies allowed for smaller and smarter electronic designs find their way into our daily lives. Thus, the third industrial revolution started.

Today, we are in a transition period between the third and fourth industrial revolution (Industry 4.0). Producers introducers mechanization, assembly lines, simple automation technologies during the first three industrial revolutions. Technological advances have developed our thinking, widened our world vision and enabled us to overcome major obstacles in production efficiency. A similar thinking route is waiting us in the near future. New industries built on old foundations are going to be stages where advanced digital technologies, artificial intelligence and cloud-based data can help us find new solutions.

Advanced Digital Technologies and Production Processes

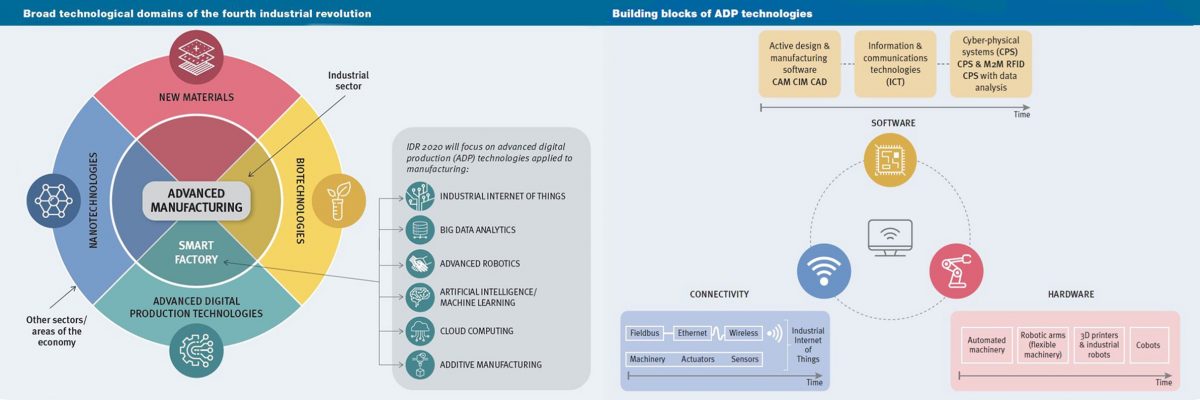

Advanced digital production technologies include but are not limited to new materials, internet of things, big data analysis, advanced robotic technologies, cloud computing, additive manufacturing, artificial intelligence supported manufacturing, nano and biotechnological production. It is likely that these new generation of technologies will affect many, many sectors in the future. But it is unlikely that this will happen overnight. İt is more likely that integration of these technologies into industries will take place more organically. Once prodcution facilities integrate tevchnology into their workflow, data sharing, deep learning networks, artificial intelligence, internet of things and remote-controlled machine and hardware integration will form smart production platforms. Today’s production areas and machines will take up a smaller percentage of factories.

Researches predict that the factory equipment of the future will be based on three high-end technologies: software, informatics and connectivity. (Software, information, connection) Software technologies will include computer aided production, information and communication technologies and data analysis. These factories will create IT-equipped automation platforms, industrial robots, three-dimensional industrial printers and co-bots (robots working together). Connectivity technologies will comprise systems such as IOT terminals, embedded sensors, wireless communication protocols, and the Internet of Things. More striking, and perhaps most importantly, product feedback will take place by the user and with a constant stream of data. Artificial intelligence and deep learning technologies will define the concept of sensitivity in production against these feedbacks. In this way, it will turn into a transitive concept covering the product development and production phases.

With the development of today’s production systems in terms of technology, factories will be fully equipped with cyber-physical systems. Training these systems with data analysis will eliminate the danger of human-robot relationships in factories and will enable robots to work in coordination with humans. Likewise, the robots of the future will have the capacity to communicate as a group and solve problems simultaneously during production.

Advantages of Advanced Digital Production

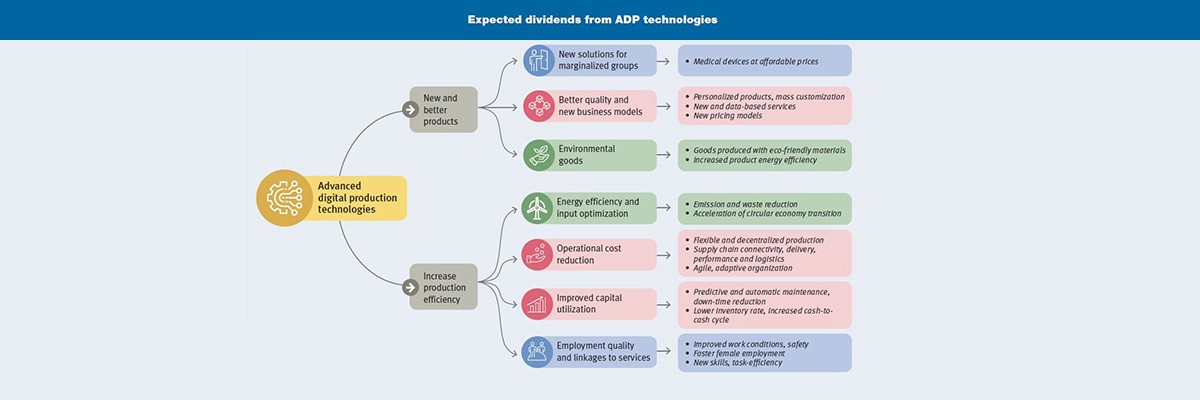

One advantage of applied high-end technology, besides higher production efficiency, will be better user experience. Communication technologies will allow marginalized populations such as workers with poverty wage to become a part of global data sharing. It will ensure sustainability by opening up new business models in the market. Product quality will no longer be a concern for brands who will focus on increasing the quality of user experience. Likewise, these technologies will optimize the use of energy and capital by reducing production costs and improving business conditions.

Smart factories will optimize energy use. Moreover, they will enable us to transition into a circular economy by reducing emissions, by-products and waste. Technologies of the future will shorten production process with the help of flexible and decentralized production, expanding the chain link, shipping, performance and logistics. In addition to this, Industry 4.0 factories will optimize the use of capital by simplifying repair processes and shortening use cycles with smart repair systems. High-end digital production technologies will increase on-site safety and champion recruiting a diverse range of workers. BlockChain technologies, will enable safe and secure sales and agreement processes and further simplify global trade. Many business conducts will become digital and operate simultaneously to production.

Advanced digital production will introduce medical technologies and information technologies to marginalized groups. Future production technologies will become a catalyst in the invention of new business models. Particulary businesses dealing with highly-customized products, mass customization, new payment systems, data-based designs and services. At the same time, products of the future will be produced in an environmentally friendly way with the ivention of new materials and reduced energy consunption. One of the most important developments will be the transparency of production processes. Production transparency of factories to government institutions and even non-governmental organizations, will offer new opportunities for measuring and limiting the human carbon footprint.

Examples of Advanced Digital Production Around the Globe

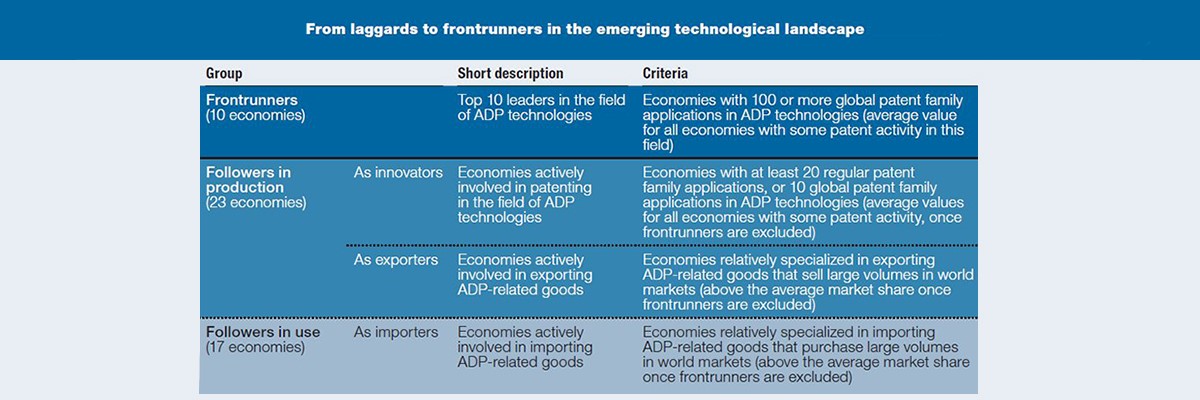

Many countries around the world are adapting advanced digital production at different speeds. Although, advanced production has become widespread in few countries, many countries are still lagging in the process and only now started preparing investment plans to bring these technologies to their factories.

Today, 10 countries aptly named as the front-runners, make up 90% of the research and inventions on advanced digital production. Currently, the sales of front-runner countries constitute 70% advanced digital technologies market. 40 countries closely follow the aforementioned countries in the use advanced technologies, albeit more conservatively. Finally, researchers highlight the chances new of technologies to increase and improve the prosperity these 40 countries. Unfortunately, adaptation of high-end production technologies by developing countries relies on the ability to access educational opportunities and previous research.

Mauritius, a country that is investing in advanced production technologies has taken investing to a state level. The Ministry of Technology and Innovation of Mauritius has written a Digital Development program up to 2030. The program notes factors, obstacles and targets required for the adaptation advanced digital production. Among the goals noted by the Ministry are development of information infrastructure, technology and the creation of necessary environments for this development.

Contribution of Makerspaces to Advanced Digital Production

Some advanced digital technologies are not yet used in mass production. Yet these technologies have already started providing new opportunities for personal and small scale producers. Communal studios, also called MakerSpaces allow access to 3D printing equipment, laser cutting and shaping technologies personal and small scale production. Makerspaces also introduce professionals, students and amateurs who are interested in such new technologies. Makerspaces increase interest digital production technologies and support design activities. Communal studio spaces democratize innovation by bringigng advanced digital production technologies to members of lower socio-economic groups. In comparison, countries view Makerspacers as a tool to spread use of digital production. Some resreachers predict this type of production will form basis of “Micro Production” centers in the future and these production studios will replace giant factories.

Transitioning to Digital Production

Advanced digital technologies which is the main componenet of fourth industrial revolution will increase productivity. Morevoer they will improve and production quality and give less developed countries a chance to participate in the global market. Countries with current plans and investments to adapt digital technologies will have advantages in the long run. Researchers recommend that countries which want to benefit from these advantages, direct the genersal public interest towards these technologies and to make them accesible. This transformation makes it possible for other countries to catch up to industrialized countries. Advanced production is a great opportunity for countries and companies to build their industry from ground up with fundamentally new investments.

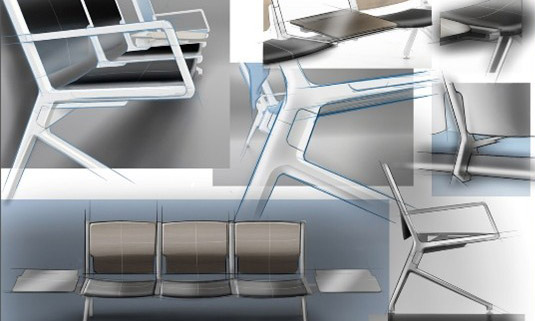

From TRT Documentary to Modern Design Philosophy: The Anatomy of Industrial Innovation with Arman Design

From TRT Documentary to Modern Design Philosophy: The Anatomy of Industrial Innovation with Arman Design  The Future of Industrial Design in Turkey

The Future of Industrial Design in Turkey  Design + Engineering: More Than Aesthetics

Design + Engineering: More Than Aesthetics